VORA TOOLING

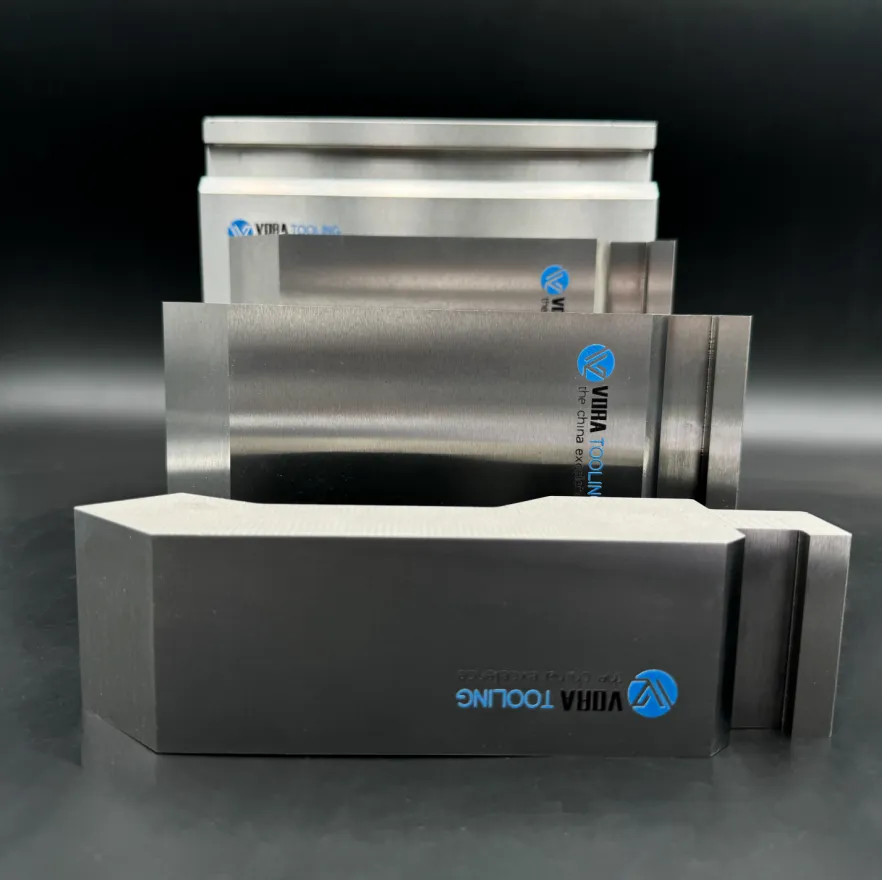

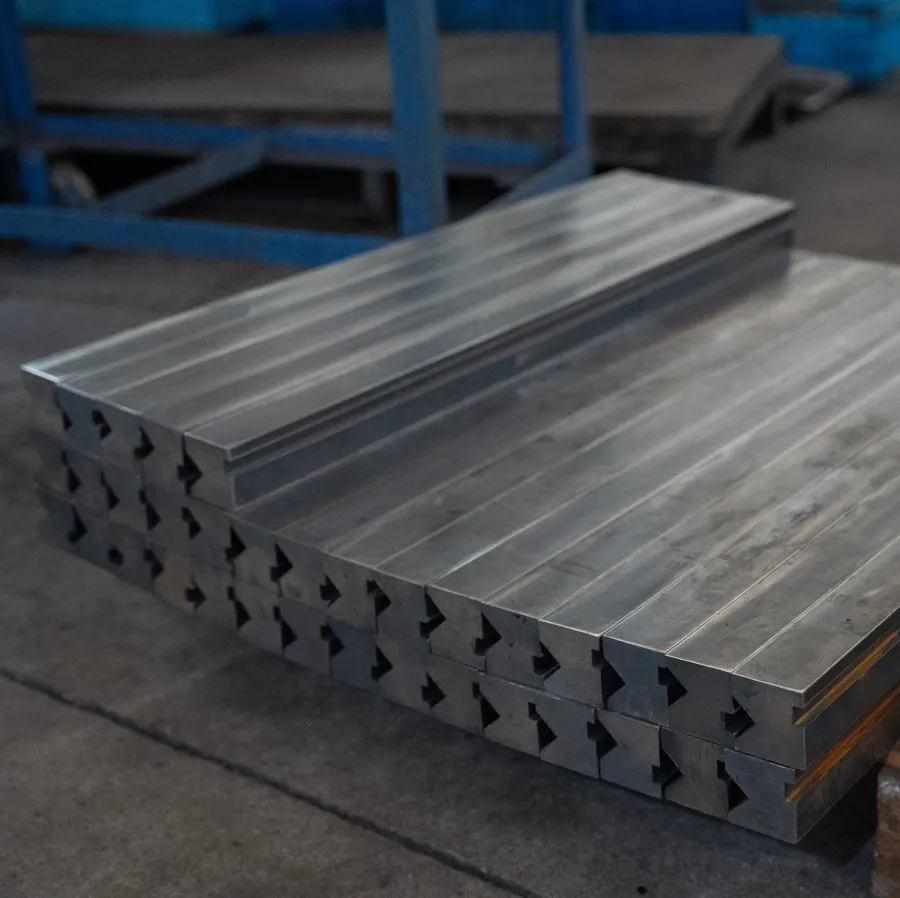

MANUFACTURING PROCESS

Our manufacturing process is like a work of art, where creative design and precision machining create high quality bending tools.

PRODUCT INTRODUCTION

VORATOOLING is one of the ten largest bending tool manufacturers in China. Our products are carefully tested and designed to last a long time using only high quality raw materials and the latest CNC machines. With unrivaled levels of precision and precision, our tools excel at even the most challenging bending tasks. Committed to innovation and staying at the forefront of technology, we have a modern machine park with equipment capable of producing tools up to 12,000 mm in size. Trust VORATOOLING to meet all your bending tooling needs and deliver superior results.

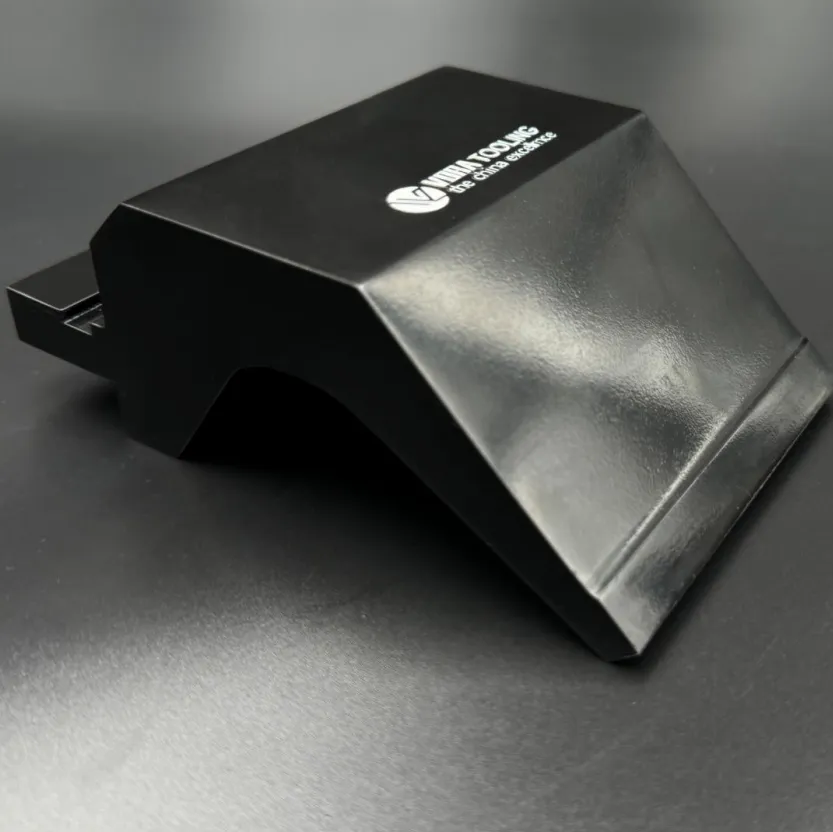

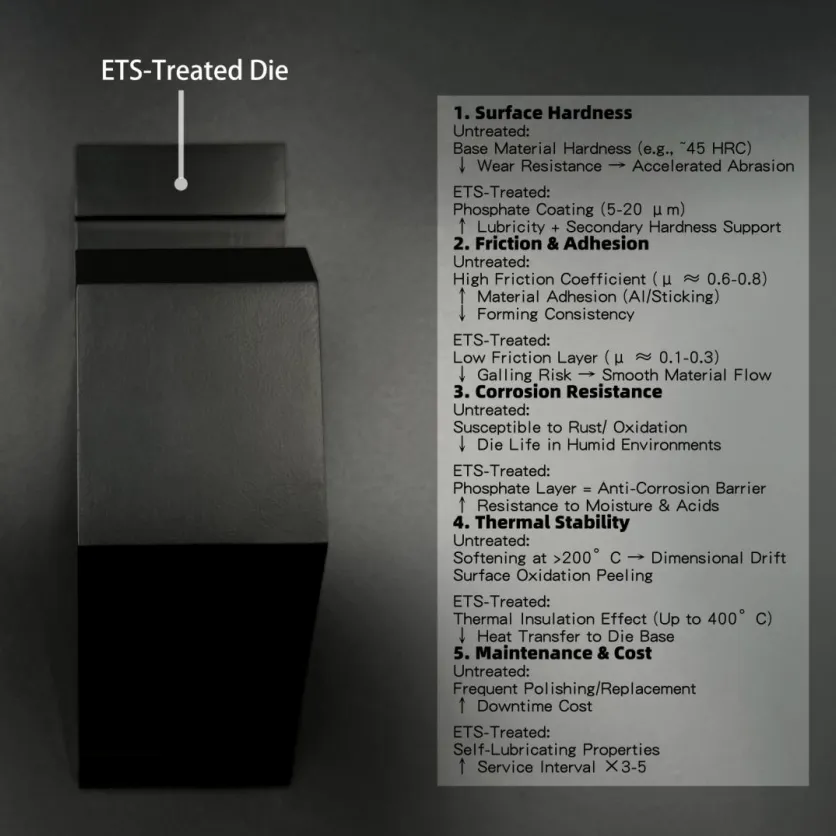

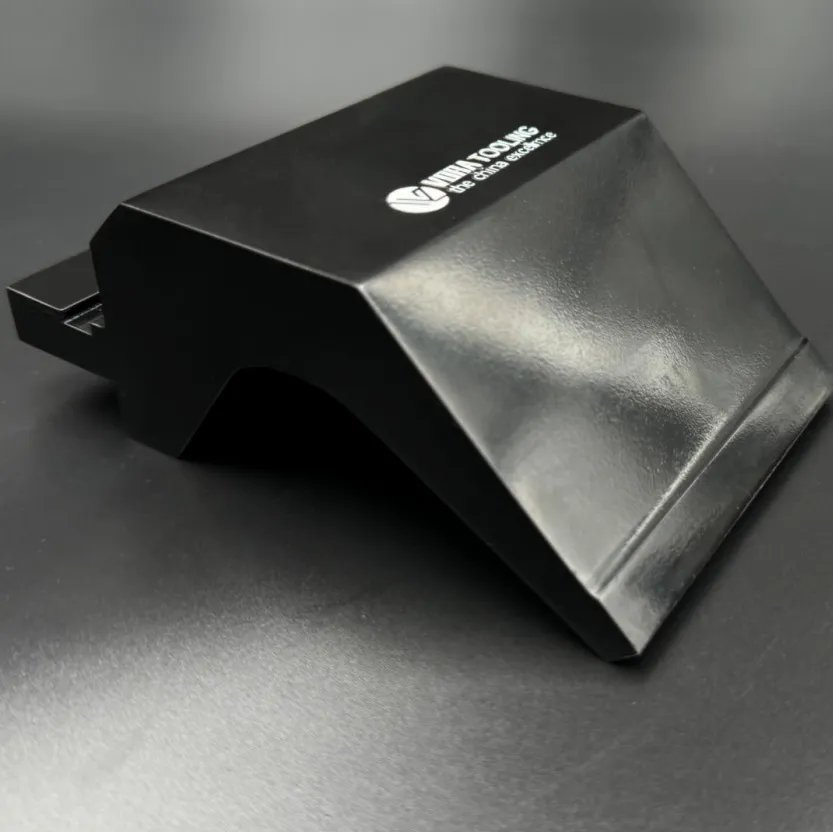

Surface Rust Prevention Treatment

Rust can significantly impact the performance and lifespan of bending machine molds. To address this, we implement a comprehensive range of rust prevention treatments.

DESIGN AND PLANNING PHASE

VORATOOLING boasts an experienced and qualified team capable of developing high quality and efficient bending machine molds to suit the specific needs and requirements of our clients. Our design team is well versed in various bending machine principles and technologies and is equipped with advanced 3D design software and analysis tools to provide comprehensive design and analysis to ensure the feasibility and excellence of our designs. Our design process is strictly standardized and controlled from design to production, ensuring the quality and technical content of each product. We always put our customers at the center of the design process, actively listening to their needs and opinions and offering optimized solutions and product designs.

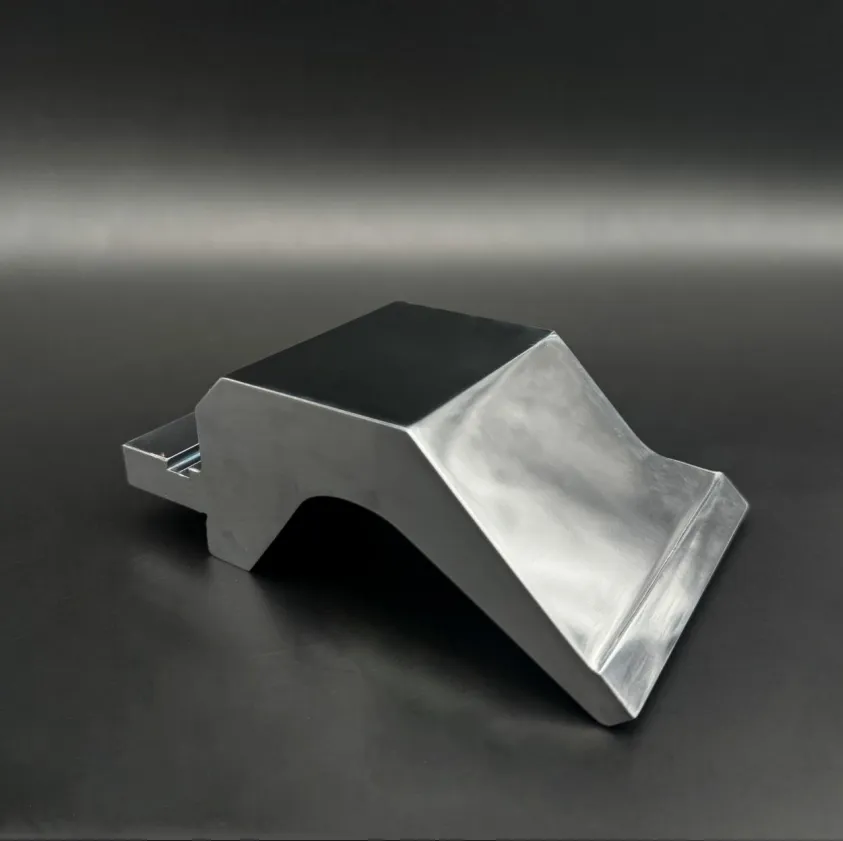

PREPARATION OF MATERIALS

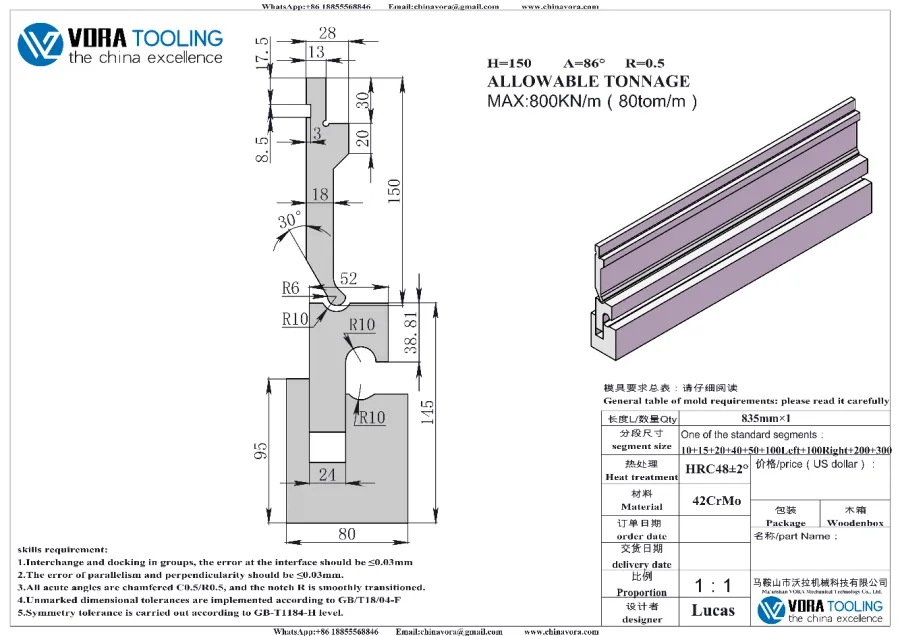

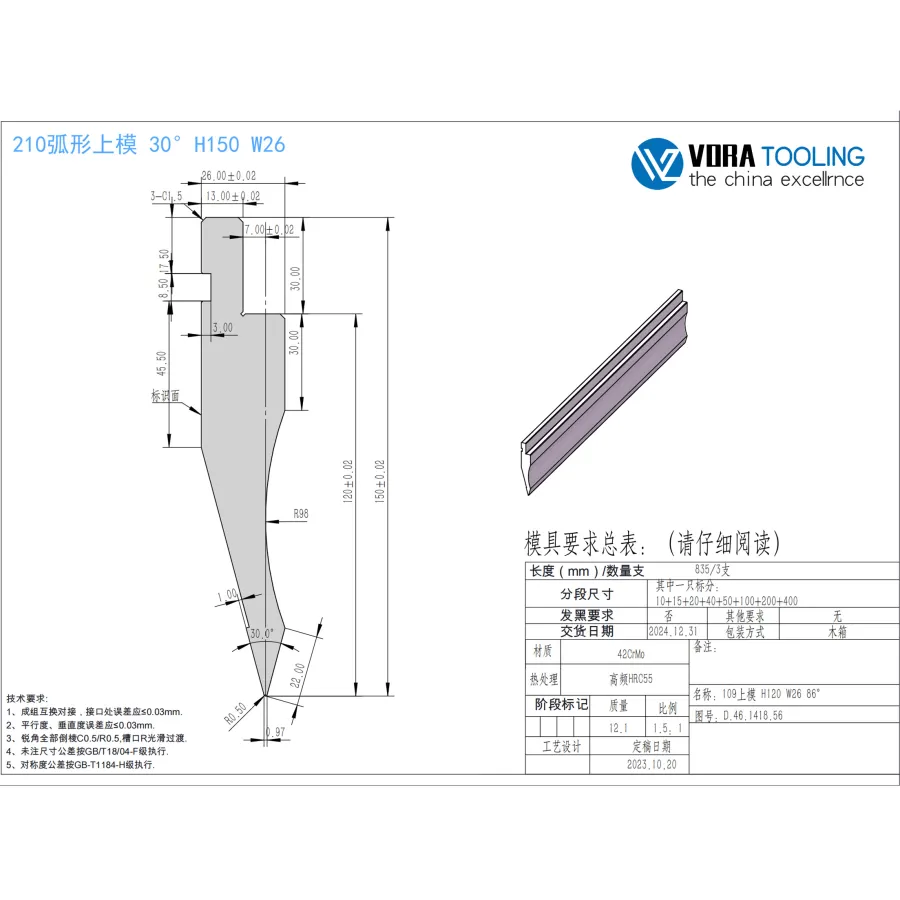

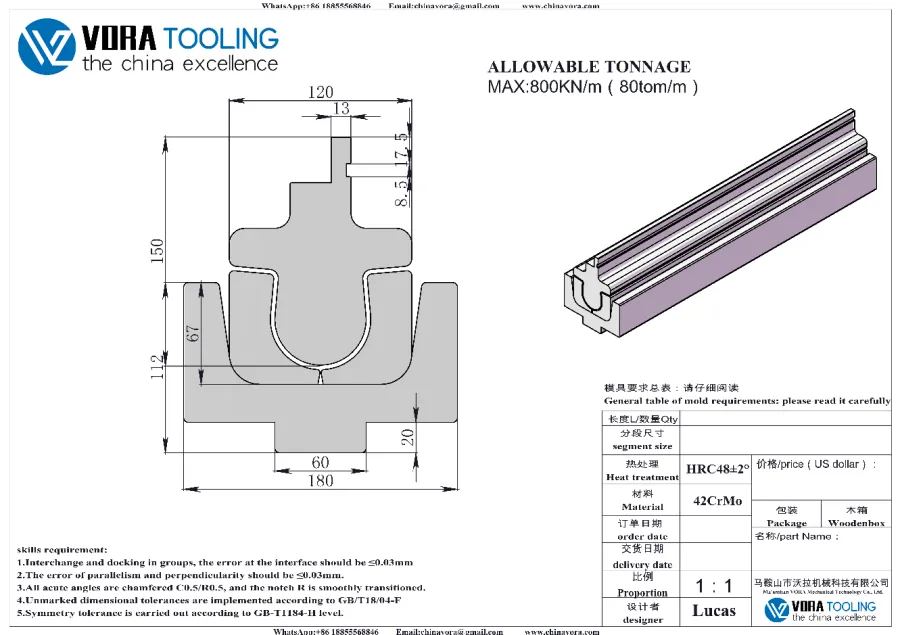

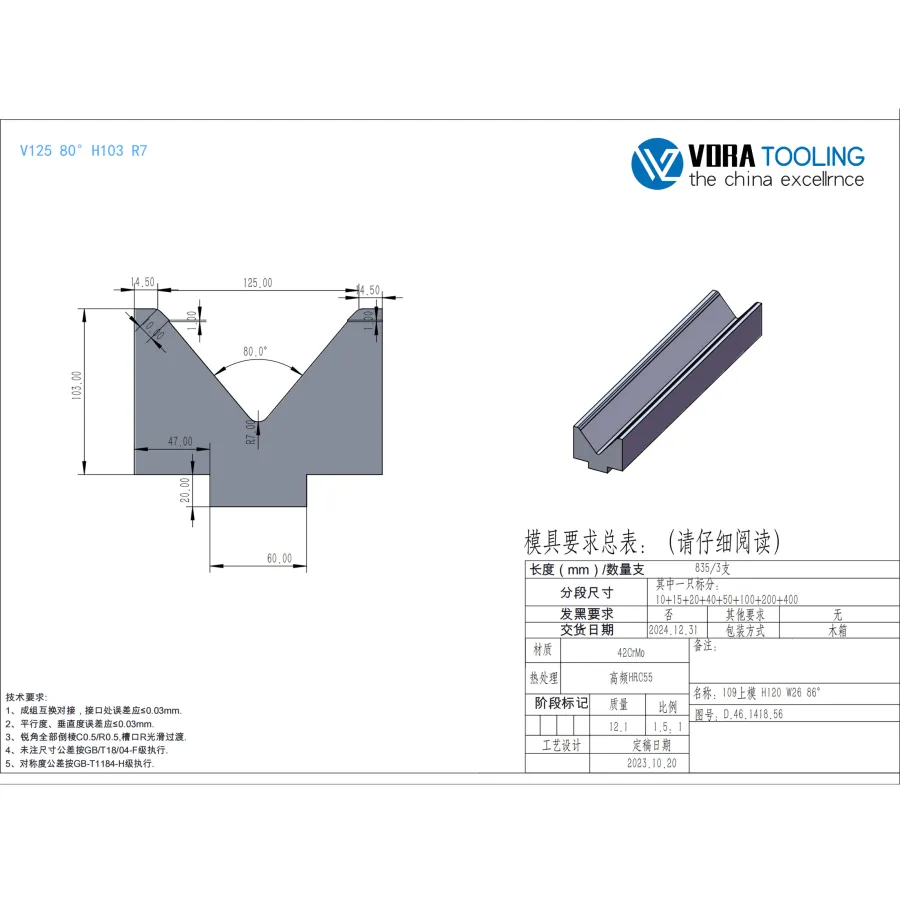

For applications requiring high strength, toughness and wear resistance, 42CrMo material is the ideal choice. It is capable of withstanding temperatures below 500 degrees, making it versatile and reliable, as well as superior manufacturability, making it an ideal choice for even the most demanding applications. In addition, we can offer material options to suit customers’ requirements.

HEAT TREATMENT

VORA bending tools undergo a rigorous full hardening process and can be laser hardened on work areas for maximum protection and hardness. With a standard stated hardness of 45-50 HRC for the entire body and 55-60 HRC for the working area (mainly die shoulders and punch tip), achieved through laser hardening of critical parts, our tools are manufactured from high quality local materials that meet the most stringent standards and conditions.

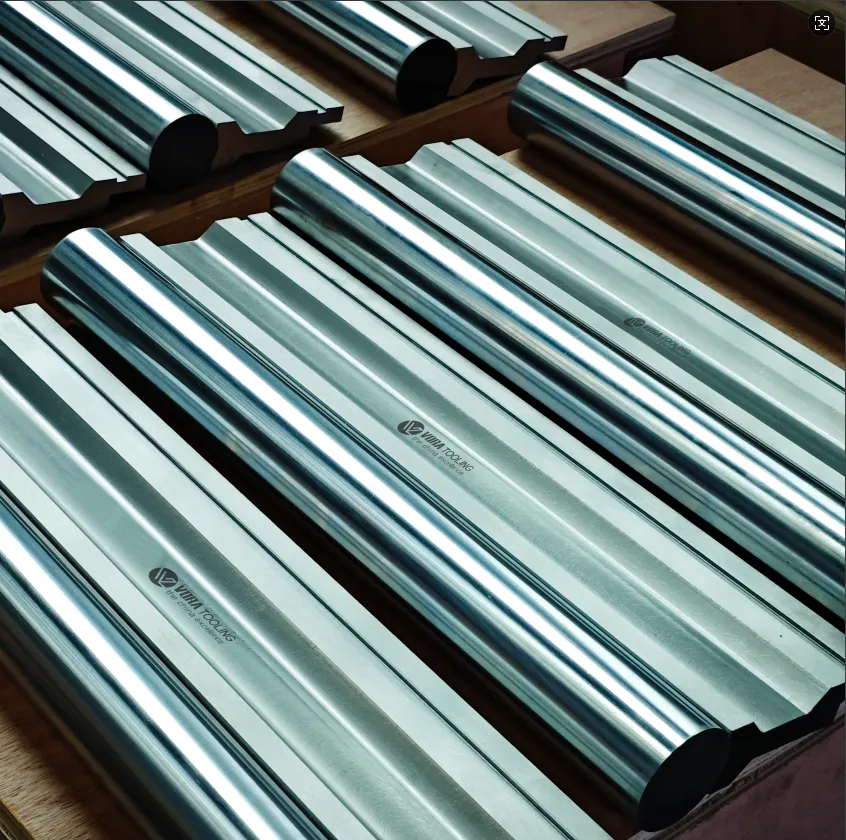

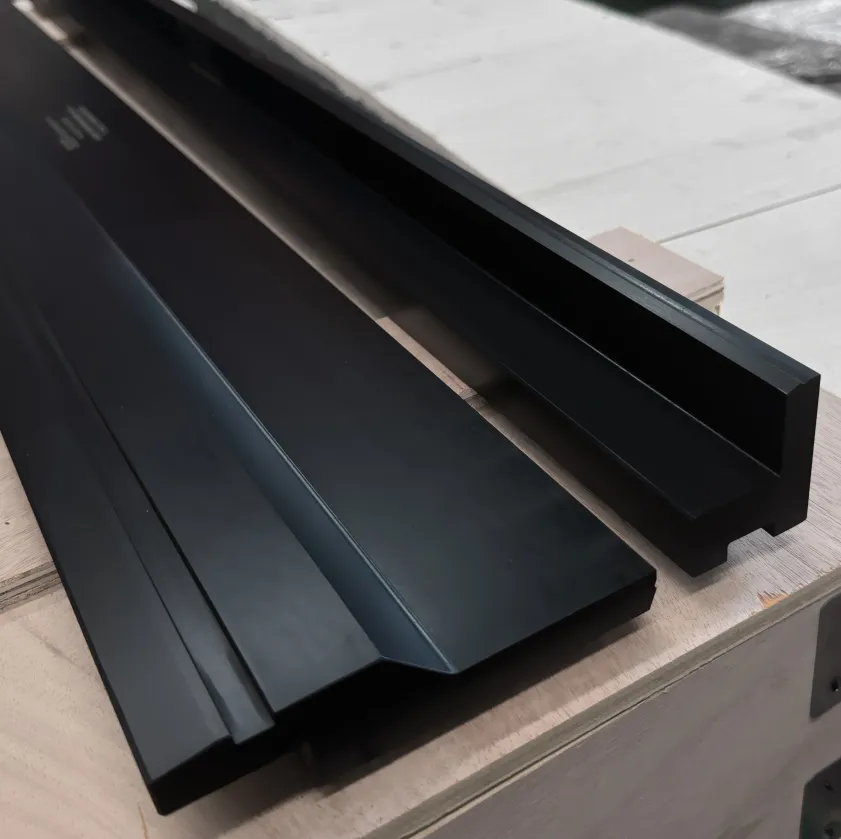

GRINDING

This process provides the treated surface with an extremely high degree of cleanliness. With our high quality CNC grinding machines you can be confident that your tools will always perform to the highest standards and meet your exact specifications.

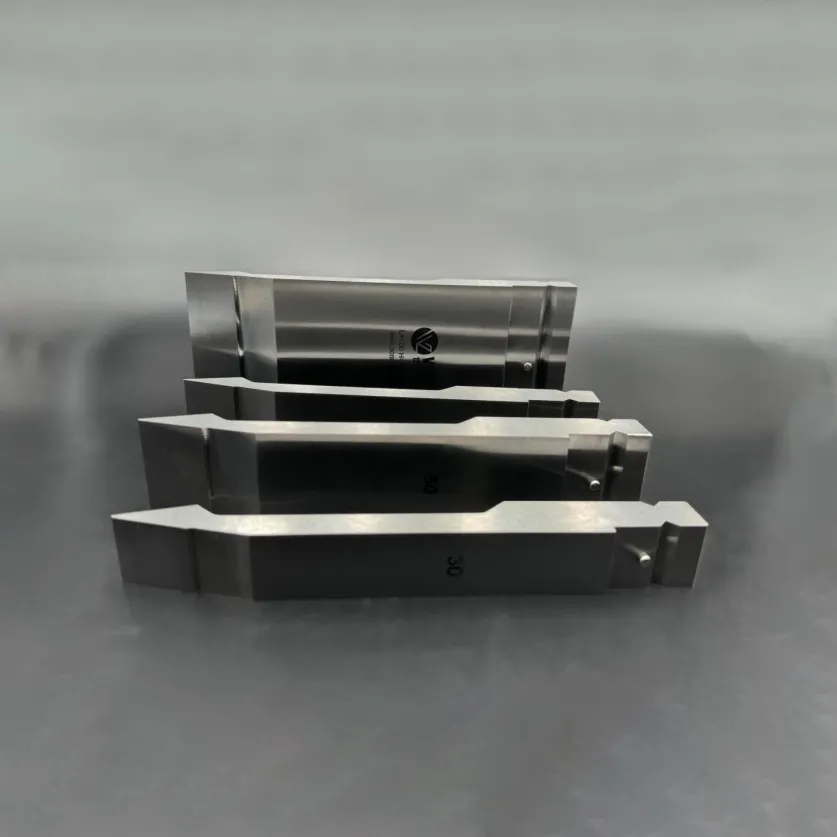

CUTTING

VORATOOING offers bending tools for length adjustment: Promecam (Euro): 835 mm, 415 mm, 835 mm sectional Trumpf system: sections 500 mm, 300 mm, 200 mm, 100 mm, 550 mm. WILA / Bystronic system: 515 mm, 300 mm, 200 mm, 100 mm, 550 mm sectional LVD system: 510 mm, sections 550 mm. We also provide long configurations 6000-12000mm for flexible machines. Trust us to develop customized solutions tailored to your flexibility requirements.